One of our Customers Gavin came across a slight issue when he had a crash and realised it can be fixed in future by adding a small washer. If you get your Falcon 250 ,you may want to put this washer in.

Symptoms

- LEDs under the 4 arms do not turn on

- LED on/off switch heats up – eventually smell burning

- All other electrical functions work – motors work, controls all function fine, quad even flies fine

Cause

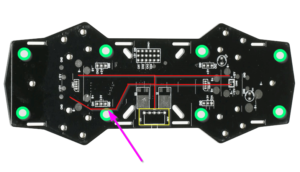

Below is a layout of the falcon PCB – the green circles indicate where the pillars/beams go to support the top carbon fibre sheeting (to create the housing for all internals), the yellow box indicates where the LED on/off switch is and the red lines (though not exactly to scale or exact paths) shows how electricity is passed from the switch out to the 4 arm LEDs….

The Pink arrow indicates where I found a problem.

For some reason, one of the power lines that runs out to one of the arm LEDs runs directly under one of the pillar/beams. If you follow the lines from the switch out to all 4 of the LEDs you will find that only ONE of them travels anywhere near one of the pillar/beam insert holes…..the other 3 lines well and truly avoid any close proximity to the pillars/beams.

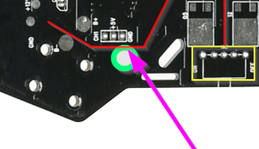

When I took apart the falcon, I removed all the pillar/beams and that is when I spotted clear melting/heat damage under this one aluminium pillar/beam marked by the green circle/pink arrow…

The area of the PCB directly under this one pillar appeared to have the black paint/coating scraped off…..which of course was exposing the copper PCB line for this LED arm to the aluminium pillar/beam and the steal screw that holds it on there. When the battery was connected and the switch turned on, electricity was stopping/shorting right here under this pillar/beam. What I believe actually caused the electrical short was a crash that I had with the quad before any of these symptoms were noticed. I crashed the quad and that resulted in a broken arm – I replaced the arm and when I screwed everything back together, the quad was exhibiting these symptoms. So what I think happened was the crash actually resulted in a shunt of this particular pillar/beam which ‘scratched’ the black coating off the PCB directly under this pillar/beam….

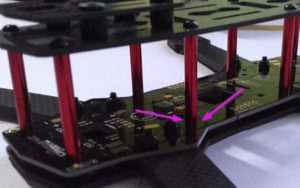

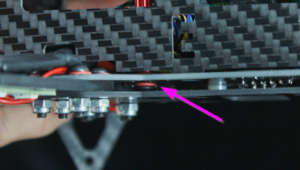

If you look around the Falcon, you will notice that some of the screws actually have these non-conductive red washers….

How ever none of the pillar/beams have these washers between them and the PCB……but really, only ONE of the pillars need a non-conductive washer between it and the PCB and that is because there is a copper line that runs directly under it……

This problem is solved by

A. not crashing your quad

B. put a nonconductive washer under this pillar. Once I placed a washer under this pillar and screwed everything back together – no more shorting issues.